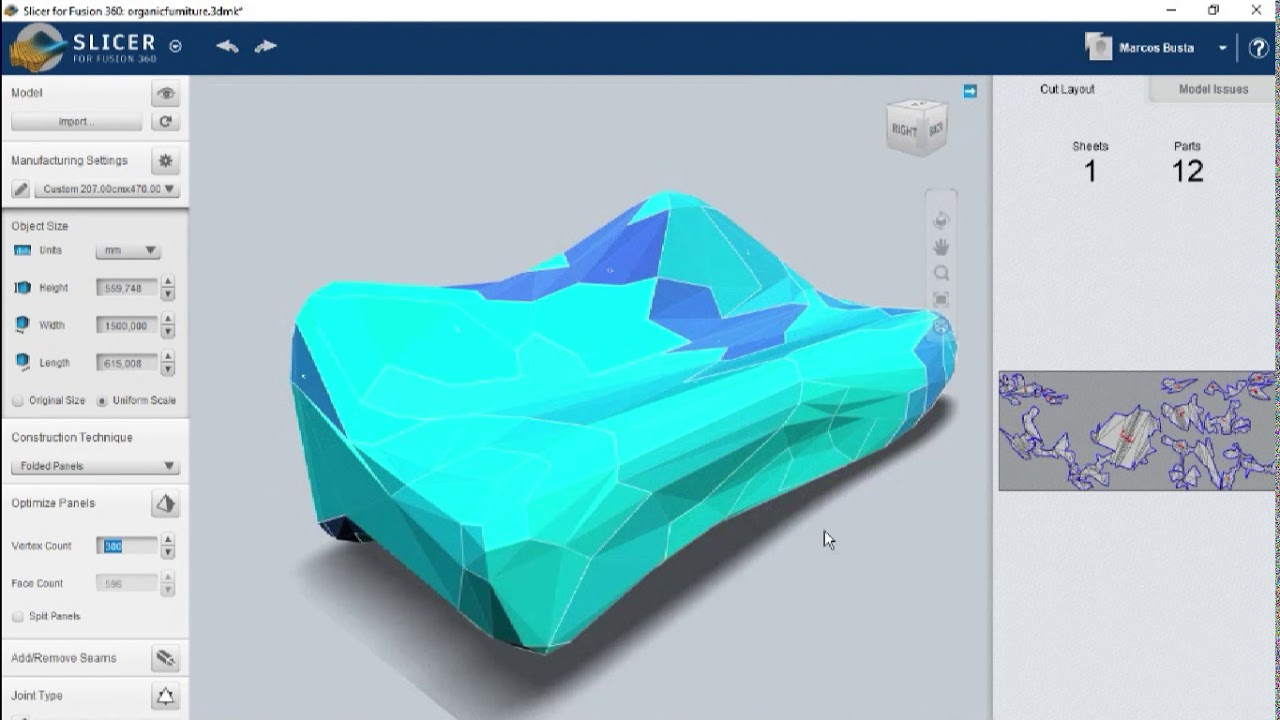

Along with that, 4 pins and 25 magnets make it easy to replace the flex plate perfectly – even with one hand. But we also don’t recommend using or adhesion structures for UltiMaker materials (except PC, ’s PC). Not only do you not need tools to pop a printed part off. A PEI-coated flexible steel build plate makes a big difference to productivity. The build stack has also been completely redesigned. To further enclose the build chamber the S7 only has one magnetically latched door. This filters the exhaust air of every print and also improves build temperature stability. It now includes an integrated Air Manager. The UltiMaker S7 is built on the success of the UltiMaker S5 and its design decisions were heavily based on feedback from customers. I know I am obviously doing something very wrong at some stage but I cannot find a solution.Ĭan anyone please please tell me how to solve this ? I have tried, combine in the Mesh tools of fusion360, even converted the Brep to a mesh and then combined, stitched, played around in Meshmixer, just about every conceivable way I can think of, to stop the Cura slicing stage adding this infill layer across the open neck of the mesh where it joins the extruded ring creation. It fills a 5 layer thick sheet right across the entire open base at the level where the "mesh joins the solid ring into which it is embedded. However as soon as it is sliced (again it performs this perfectly) then when I preview or even create the 3D print it this is where the problem shows up. Using Cura 4.4 I can then open the file, land it on the base, again all looks great, even viewing through the build plate from underneath again all looks fine. When I highlight the entire object and create an stl file for printing -again all seems ok The mesh was then "embedded" into the ring.Įverything looks fine, when I rotate the object about in all planes I see exactly what I want. Drew up a base ring for it to sit on and in inserted into fusion360, modded the ring extruding sections sections to create my required base with fixing lugs etc.

started with an imported scan of a very thin walled hollow object. I am using a combination of Autocad 2017, Fusion 360 and Meshmixer. Tell me what I am doing wrong or better still help me fix it. So pleeeeease please someone out there take pity and help me out.

To solve this issue without any progress,(I hate to add up the wasted time)

I am a real beginner, so apologise in advance if I am doing something so totally obviously wrong to you experts out there, but I have been trying for months, with hours and hours a week

0 kommentar(er)

0 kommentar(er)